Aerospace Products

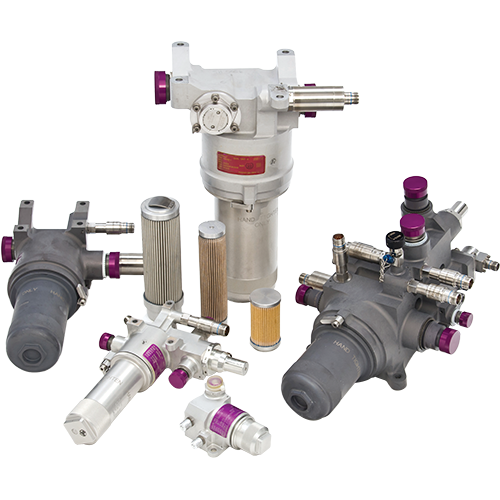

PTI’s custom designed filter manifolds integrate independent fluid system into one compact and efficient manifold providing greater reliability and improved maintainability while optimizing weight and mission performance. International customers have selected PTI as their source for filtration and fluid control products.

PTI Technologies engineers reliable, high-performance and fully integrated filtration solutions for aircraft fluid systems. PTI’s complex filtration and fluid control manifolds ensure maximum protection and efficiency against contaminants in systems with operating pressures up to 5,000 PSI. Technical innovation enhanced by our customer focus has made PTI a trusted partner in the aerospace market.

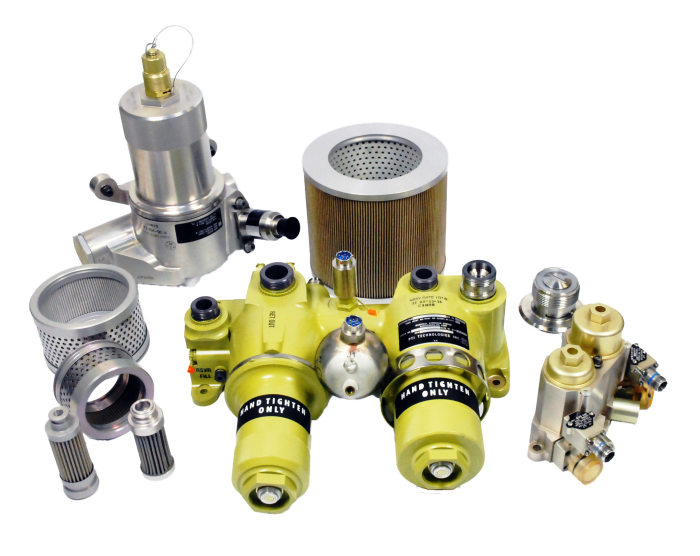

PTI has a extensive pedigree in commercial and military aviation, but we also produce products for business jets and regional aircraft. The hydraulic filter modules for the Falcon 7X are examples of complex multi-component modules and incorporate the following components:

- Pressure, case drain and return filter elements

- Relief, bypass and check valves

- Pressure switches, pressure transducers

- Electrical / visual delta-P indicators

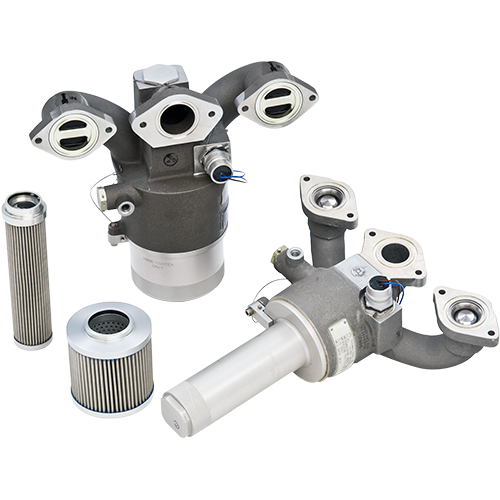

In addition to multi-component modules, PTI also designs and manufacturers filter sub-assemblies for direct integration into engine, gearbox or pump housings. The engine lube filter sub-assembly for the JSF F-135 engine consists of a filter bowl, filter element and a combination valve assembly with by-pass, shut-off and reverse flow functions.

PTI Technologies designs and produces many of the hydraulic filtration components on Boeing’s family of aircraft. Our product content ranges from individual filter elements to complete integrated hydraulic system modules like the Boeing 767 Engine Driven Pump / Air Driven Pump Module.

PTI Technologies designs and produces many of the Hydraulic Filtration Applications on Boeing’s family of Aircraft. The Boeing 787 liquid cooling system provides cooling flow to the Primary Electronics Cooling System (PECS), the Integrated Cooling System (ICS) and the Forward Cargo Air Conditioning System (FCAC) – which PTI provides the filtration package modules for all three systems.

PTI has developed a number of innovative filter designs and aviation firsts. The RR 250 Combined Engine Fuel Assembly filter module is a unique design which incorporates engine lube and fuel filters in the same module. This design provides significant weight savings and a smaller space claim as well as the added benefit of cooling the lube oil via thermal transfer with the relatively cool fuel.

PTI’s multi-component modules combine a number of functions into a compact package. The EJ 200 engine lube oil filter module for the Eurofighter incorporates both pressure and return lube oil filtration as well as bypass valves and electrical / visual indicators.

PTI’s custom-designed Radar Coolant Filter Module provides Liquid Cooling Filtration in support of the radar fluid systems integrated into one compact and efficient manifold providing greater reliability and improved maintainability.

Key Features:

- Face Seal Design

- Filters Polyalphaolefin (PAO)

- 180 psi Operating Pressure

- Differential Pressure Indicator

- System Relief Valve

- Shut-off Valve

- Bypass Valve

PTI’s filter modules support military aircraft systems to handle vital functions – such as hydraulic actuation, fuel distribution, lubrication systems, environmental control, avionics and electronics all of which depend on fluid cleanliness to perform safely and reliably during mission-critical operations.

PTI’s filter modules are available on a wide range of military platforms such as:

- F-35

- F-15

- F-16

- F/A-18

- B-2

- U-2

- KC-46

- Eurofighter

Platform

GE T700/CT7

UH-60 Black Hawk

AH-64 Apache

Function

Performs dual functions on gas turbine engines:

• Provides hot air flow for engine anti-ice protection

• Automatically bleeds air from the engine during the starting cycle

Platform

CH-148 Cyclone

SH-60/MH-60 Seahawk

HH-60W (CRH)

Function

Jettison fuel from fuel tank

Platform

CH-148 Cyclone

Function

Vents fuel tanks and prevents over pressurization

Platform

F-14 Tomcat

Function

Controls fuel flow; used as a wing tank shut off

Platform

KC-10 Extender

Function

In-flight aerial refueling/fuel transfer

Platform

V-22 Osprey

Function

Provides a single aircraft fuel line connection to refuel and defuel through dual valve sections

Platform

Boeing F-15 Eagle

Function

Used to engage a flying boom from a tanker aircraft for aerial refueling

Platform

KAI KF-21 Boramae

Function

Used to engage a flying boom from a tanker aircraft for aerial refueling

PTI Technologies designs and produces a wide range of hydraulic filter elements used in today’s commercial and military aircraft and ground support systems. Filter elements comprised of depth-type filtration media combine high efficiency particle removal while optimizing contamination capacity. Operating environments include pressures up to 5,000 psid and temperatures ranging from -65°F to 350°F.

PTI provides filtration solutions for engine applications ranging from the PT6 to the PW4000 series engines. Applications include fuel, lubrication and pneumatic systems. Filter elements of the constructed of depth-type filtration media or woven wire mesh are offered in both disposable and cleanable configurations.

In addition to pleated filter elements, PTI provides screen, strainer and metal edge type filter elements for use in last chance, fuel wash flow, scavenge lube oil and other systems requiring protection for downstream components.

Drawing on our longstanding experience in the design, and production of metal fiber media filter elements, PTI has led development of improved hydraulic system filter elements for the US Army. Early tests have shown a significant improvement in system cleanliness, on stream life and resistance to cyclic flow contaminant migration.

PTI Technologies’ random fiber filter media is the highest performance media on the market today. PTI’s 421® Metal Fiber Media element design extends the life of components and reduces annual maintenance cost, thereby providing a higher level of operational reliability and improved safety.

Platform

- AH-64 Apache

P/N 7595726-101 - H-60 Black Hawk

P/N 7596335-101 - Aviation Ground Power Unit (AGPU)

P/N 7600570-101

- Service Interval: C-check

Boeing Series

- 737-700

- 737-800

- 737-600

- 37-900

- 747-400

- 757-200

- 757-300

- 767-200

- 767-300

- 767-300F

- 767-400ER

- 777-200

- 777-300

- 777-300ER

- 777-200LR

- 777F Series

Designed to remove airborne particles including dust, pollen, lint, smoke, spores, hydraulic mist, bacteria, viruses and other contaminants

- 99.97% efficient in removing 0.3 micron particles

- Meets requirements of a 1200 CFM system

- Service Interval: C-check

- Protects from airborne bacteria and viruses

Boeing Series

- 737-300

- 737-400

- 737-500

- 737-600

- 737-700

- 737-800

- 737-900

- 757-200

- 757-300

Designed to remove contaminants from the avionics equipment cooling air supply

- Service Interval: C-check

- 100% efficiency at 15 micron particle size

Boeing Series

- 737-600

- 737-700

- 737-800

- 737-900

- 757-200

- 757-300

Designed to remove contaminants from the electronics equipment cooling air supply

- Service Interval: 2A-Check

Boeing Series

- 717-200

- MD-90-30

- 99.97% efficient in removing 0.3 micron particles

- Skydrol® Tested

- Protects from airborne bacteria and viruses

Embraer Series

- 170-100 STD

- 170-100 LR

- 170-100 SU

- 170-100 SE

- 170-200 STD

- 170-200 LR

- 170-200 SU

- 190-100 STD

- 190-100 LR

- 190-100 IGW

- 190-100 ECJ

- 190-200 STD

- 190-200 LR

- 190-200 IGW

Designed to remove contaminants from the avionics equipment cooling air supply

- 99% efficient for particles 50 micron and greater in an airstream at 1500 SCFM

- Service Interval: C-check

Boeing Series

- 777-200

- 777-200LR

- 777-300

- 777-300ER

- 777F

Designed to remove airborne particles including dust, pollen, lint, smoke, spores, hydraulic mist, bacteria, viruses and other contaminants

- 99.97% efficient in removing 0.3 micron particles

- Rated Airflow: 1500 SCFM

- Service Interval: C-check

- Protects from airborne bacteria and viruses

- Skydrol® tested

Boeing Series

- 767-300

Designed to remove airborne particles including dust, pollen, lint, smoke, spores, hydraulic mist, bacteria, viruses and other contaminants

- 99.9% efficient in removing 0.3 micron particles

- Rated Airflow: 680 SCFM

- Service Interval: C-check

- Skydrol® Tested

Boeing Series

- 747-400

- 747-400D

- 747-400F

Designed to enhance taste and eliminate odor

- Disposable

- 5 Micron

- Flow Rate: 1 gpm

(3.8 lpm) - Capacity: 3000 gallons

(11 356,2 liters) - Certified to NSF Standards

Airbus Series

- A318

- A319

- A320

- A321

- A330

- A340

Boeing Series

- 737

- 777

- CRJ 700

- CRJ 900

Designed to enhance taste and eliminate odor

- Disposable

- 5 Micron

- Flow Rate: 1.3 gpm

(4.9 lpm) - Capacity: 5000 gallons

(18 927,06 liters) - Certified to NSF Standards

Airbus Series

- A318

- A319

- A320

- A330

- A340

Boeing Series

- 747

- DC-9

- DC-10

- KC-10

- MD-81

- MD-82

- MD-83

- MD-87

Designed to enhance taste and eliminate odor, and protect against pathogens, parasitic cysts, disease, bacteria and viruses

- Disposable

- 0.4 Micron

- Flow Rate: 1 gpm

(3.8 lpm) - Capacity: 1000 gallons

(3785.4 liters) - Certified to NSF Standards

Airbus Series

- A318

- A319

- A320

- A321

- A330

- A340

Boeing Series

- 717-200

Designed to enhance taste and eliminate odor

- Disposable

- 50 Micron

- Flow Rate: 1 gpm

(3.8 lpm) - Capacity: 3000 gallons

(11356.2 liters) - Certified to NSF Standards

Airbus Series:

- A318

- A319

- A320

- A321

- A330

- A340

Boeing Series:

- 737

- 747

- 757

- 767

- 777

This rolling diaphragm indicator detects differential pressures as low as 5 psid +/- 0.5 psid up to 15 psid +/- 1.5 psid while maintaining a size compact enough to be mounted in a SAE-AS33514-8 port. High pressure sensing port is located radially on the OD just below the .750-16 UNJF mounting threads with the low pressure sensing port opposite and along the axis of the signal button. Signal: Visual. Reset: Manual.

Electrical and visual design couples MIL-S-8805 microswitch to the magnetic pop-out button. The mechanical motion of the pop-out button drives the snap acting SPDT microswitch. The switch can be wired for normally open or normally closed circuits. Hermetically sealed, gold contact switches recommended for all high temperature (to 500ºF) or low load applications (6 Volt, 0.010 amp circuit). Many mounting configurations and electrical connectors are available, or can be built to customer specification. Signal: Electrical and Visual. Reset: Manual (Automatic reset also available).

This indicator has a high pressure sensing port located at the bottom of the indicator, opposite and along the axis of the signal button. The low pressure sensing port is located radially. Signal: Visual. Reset: Manual.

Compact design provides a visual pop-out button signaling impending bypass. With the application of additional pressure, the indicator cracks to permit bypass. The standard unit designed for use with a 0-12 GPM flow rate, 50 psid +/- 5 psid actuation, 60 psid +/- 10 psid cracks with a 10 psid minimum between actuation and crack. High pressure sensing port is located at the bottom of the indicator, opposite and along the axis of the signal button. The low pressure sensing port and bypass openings are located. Signal and bypass functions are accomplished in a very small, lightweight package. The overall length of the indicator with bypass is 1.800″ with a 0.743″ OD. Signal: Visual. Reset: Manual.