Using Robust 421® Metal Fiber Media Filtration to Enhance Aircraft System Performance and Reliability

Customers benefit in maintaining system operations and schedules, reducing maintenance downtime, extending the life of expensive system components, improving operational safety

PRESS RELEASE

January 26, 2023

Oxnard, California – PTI Technologies is honored to be featured in the December 2022 issue of Army Aviation Magazine – see page 40. PTI’s 421® Metal Fiber Media provides customers with benefits in maintaining system operations and schedules, reducing maintenance downtime, extending the life of expensive system components, improving operational safety, and ultimately, contributing savings to the bottom line.

What Causes Aircraft System Failures?

A primary cause of failure in aircraft hydraulic, lubrication, fuel, coolant, bleed air and pneumatic systems is particulate contamination and the risks from a failure are significant – increased maintenance costs, loss of aircraft availability or readiness, reduced system performance and aircraft crashes, resulting in risks to human life. The contaminants become entrained in the fluid of the aircraft systems from debris built in during manufacturing processes, ingression from external sources, and those generated during system operation. Aircraft fluids are a repository for contaminants unless some action is taken to eliminate or reduce them to acceptable levels. To survive, aircraft systems must operate reliably under extreme operating pressures, temperatures, vibration/shock, and cyclic flow conditions. Clean fluids enable this reliable performance but in such challenging conditions, standard cellulosic or micro-fiberglass media filter elements often fail. Cellulosic or micro-fiberglass media rely on adhesives to bind the random fibers to maintain structural integrity; however, these filters are prone to media migration and shedding of contaminants under stressful operating conditions such as cold startup that challenges the filter with high viscosity oil flow.

Drop-In Solution

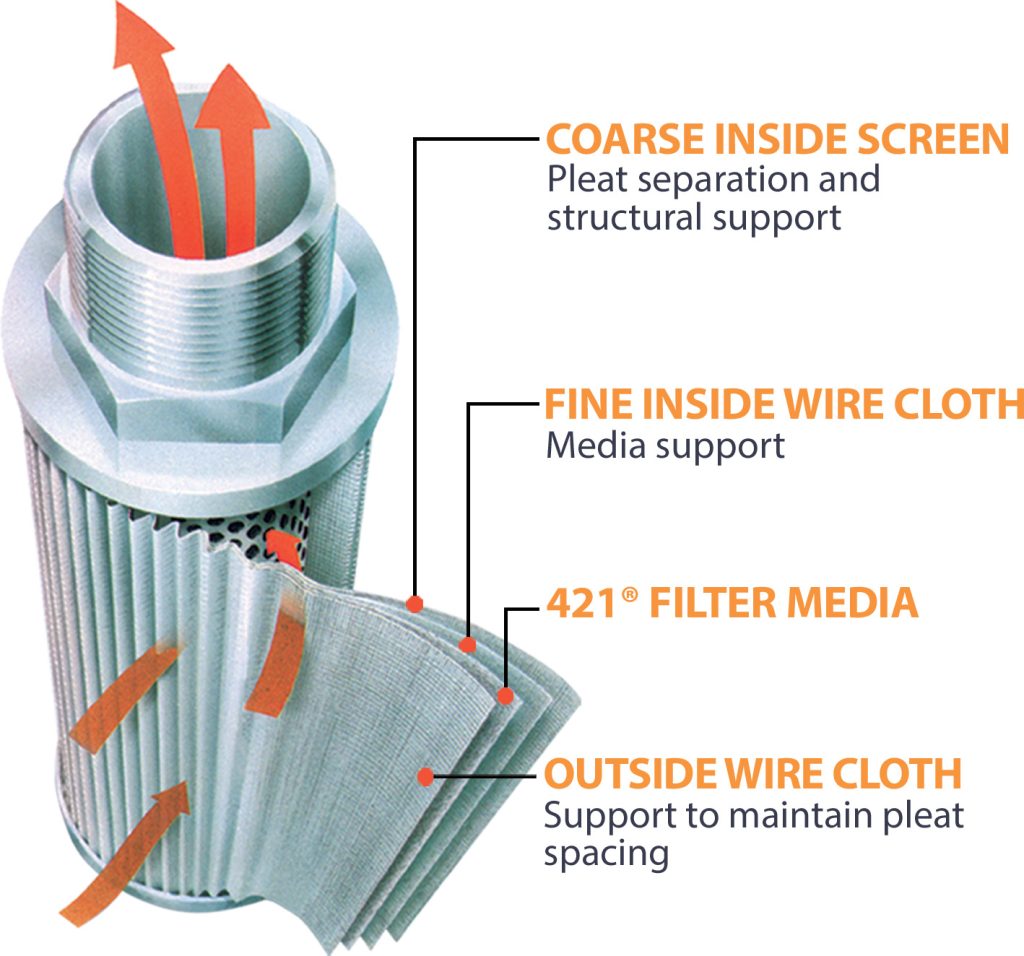

One solution is the application of filter elements with advanced random metal fiber media to aircraft filtration systems. This is a drop-in solution requiring no modification to the aircraft architecture. Like micro-fiberglass media, the metal fiber media is a porous random laid matrix, and can incorporate layers with different fiber diameters to increase depth filtration. Metal fiber media uses metallurgical sintered and mechanically compressed metal fibers, eliminating media migration, and significantly reducing the shedding of contaminants. The depth matrix of fine, yet durable metallic fibers creates a stable pore structure that is virtually unchangeable for the life of the filter. The high porosity of the metal fiber media also offers less resistance to fluid flow by minimizing changes in the direction of flow, and its low fluid tortuosity minimizes pressure drop. Advancements in the drawing of smaller diameter metal fibers and in sintering technology to maintain the robust structure while still keeping the material pliable when forming the pleated structure have moved metal fiber media into the spotlight as a solution. PTI Technologies has put significant R&D investments into process development for repeated manufacturability of metal fiber media, resulting in our proprietary 421® Metal Fiber Media.

The U.S. Army has used micro-fiberglass fiber media filter element designs for both the Boeing AH-64 Apache and the Sikorsky H-60 Black Hawk fleet of helicopters as well as the Aviation Ground Power Unit (AGPU) since their introduction into service. However, for over a decade, the U.S. Army was very unsatisfied with the fluid cleanliness of the hydraulic systems in these aircraft, as a result of the extreme flight operating conditions, and the impact this has on hydraulic system failures.

PTI Technologies worked in cooperation with the U.S. Army to lead the development and application of metal fiber media to filter fluids in challenging aircraft applications. PTI used its proprietary 421® Metal Fiber Media in the development, qualification and production of hydraulic filters for the AH-64 and H-60 helicopters as well as the AGPU start cart supporting these aircraft. Using 421® Metal Fiber Media provides superior filtration performance, and enhances system life by providing lower pressure drop and a higher contaminant retention capacity than either woven metallic wire cloth or sintered powder metal filters. 421® Metal Fiber Media is ideal for the filtration of highly viscous, high-temperature, cryogenic and corrosive fluids. It is the highest-performing media on the market today and is fully customizable to meet any design specifications.

Army Study Confirmed Desired Technology

After fielding 421® Metal Fiber Media filter elements for the AH-64, H-60 and AGPU, the U.S. Army has conducted several studies to ensure they were seeing the level of performance they desired. One analysis conducted on sixty H-60 aircraft over a two-year period at Fort Rucker, Alabama showed that after the installation of 421® Metal Fiber Media filters in the hydraulic system the Mean Time Between Failures (MTBF) doubled for critical components such as the hydraulic pump and primary servos and over a 50% increase in MTBF for Stability Augmentation System (SAS) actuators. The U.S. Army estimated that this performance improvement could save $4M per 100 flight hours if the metal fiber media elements were applied fleet-wide. Recent performance analysis of metal fiber media in the AGPU application showed that in some cases, the hydraulic fluid reached the Class 0 level of cleanliness – an unheard-of level of cleanliness. PTI’s 421® Metal Fiber Media filtration technology is performing as designed, resulting in the issuance of an Aviation Maintenance Action Message (AMAM) to convert both the AH-64 and H-60 current fleets to metal fiber media filter elements in the next three years.

Testing Standards Refined

In parallel to the development of metal fiber media filter elements, further studies by PTI and a team of engineers at Fort Rucker realized that the test methods used to qualify current filter element designs (MIL-F-8815) in the test lab, did not come close to matching the extreme conditions filter elements will see in the field. The U.S. Army engineers worked with the SAE A6 Filtration Committee, filter manufacturers like PTI and test laboratories to develop improved filter element test standards MIL-DTL-8815/31(AV), MIL-DTL-8815/32(AV) and MIL-DTL-8815/33(AV). The intent of these new standards is to evaluate filter elements under conditions that more closely resemble the operating conditions found during flight operations. This improved testing methodology combined with the field performance of metal fiber media clearly demonstrates that metal fiber media filter elements make a real difference – in performance, reliability and safety.

Capability Expansion

With our proven use on military platforms in hydraulic, bleed air and coolant applications, PTI is now bringing 421® Metal Fiber Media filtration technology into the commercial landscape for bleed air, fuel, engine and other aircraft filtration applications. We are currently in conversations with multiple airframe and engine OEMs and establishing partnerships for the future of this innovative solution. We are already applying 421® Metal Fiber Media to new high-temperature fuel filtration for engines, new high-temperature lubrication systems for gearboxes and customer fluid test rigs that support critical test of production components.

421® Metal Fiber Media dramatically enhances the performance and reliability of our customer’s fluid systems by maintaining fluid cleanliness over the life of the filter. As a result, customers benefit in maintaining system operations and schedules, reducing maintenance downtime, extending the life of expensive system components, improving operational safety, and ultimately, contributing savings to the bottom line.

Visit https://www.ptitechnologies.com/aerospace/products/421-media/ to learn more about our innovative filtration and fluid control solutions.

Current 421® Product Offering

PTI Technologies’ metal fiber filter media is the highest-performance media on the market today. It will give you a higher purity end product, a lower pressure drop, and a higher contaminant retention capacity than either woven metallic wire cloth or sintered powder metal. 421® metal fiber media filter elements are ideal for filtration of high viscosity, high temperature, high vibration, dynamic, or corrosive fluid applications.

Download 421® Brochure

Download 421® Metal Fiber Media Filters White Paper

Follow PTI

PTI Technologies is a world leader in highly-reliable filtration and fluid control equipment and subsystems and miniature CAD/PAD devices. Our product portfolio, used in hydraulics, fuel, thermal management, lubrication, bleed air, environmental air/cabin air, water systems, ejection seats, fire suppression, escape slides, missiles and munitions, is a direct result of our extensive engineering design experience and customer obsession. PTI provides innovative, value-added solutions for a full range of mission, flight and life-critical operations across the Aerospace and Defense markets.